The following page of notes will cover:

- Finishes

- Paper and board finishes

Paints:

- Stops rusting/corrosion

- Aesthetically pleasing

- Range of colours

- Saves time/money

|

- Chips/flakes away

- Environmently unfriendly

|

Uses: Bridges, metal work, brick work

Varnishes:

- Protects from dirt/sunlight/water

- Enhances look of wood

- Easy to apply

- Can't see brush strokes

|

- Can be dull colour

- Bubbles can ruin finished look

- Some varnishes are bad for the environment (brushes cleaned result in varnish into water system)

|

Uses: Hardwoods and sodtwoods

Sealant:

- Waterproof finish

- Thermal/acoustical insulation

- Electrical insulation

- Used for simple smoothing/filling

|

- Does not have great strength

|

Uses: Pipe threads, aquariums, roofs, hydraulic systems

Preservatives:

- Improves lifespan of timber

- Reduce biological corrosion

- Improves aesthetics of wood

|

- Toxic

- More effective if used to pressure treat wood

|

Uses: Wood products exposed to water and corrosion

Anodising:

How it works:

- Used to add a coating to aluminium

- An electric current is passed through an acidic electrolyte

- The metal being protected (anode) then builds a layer of aluminium oxide

- Can be done in a range of colours

- Very durable finish

- Hard finish/scratch resistant

- Thin finish - doesn't block holes in product

- Heat resistant finish

|

- Joining/machining can't be done after anodising

- Expensive

|

Uses: Window frames, bike frames

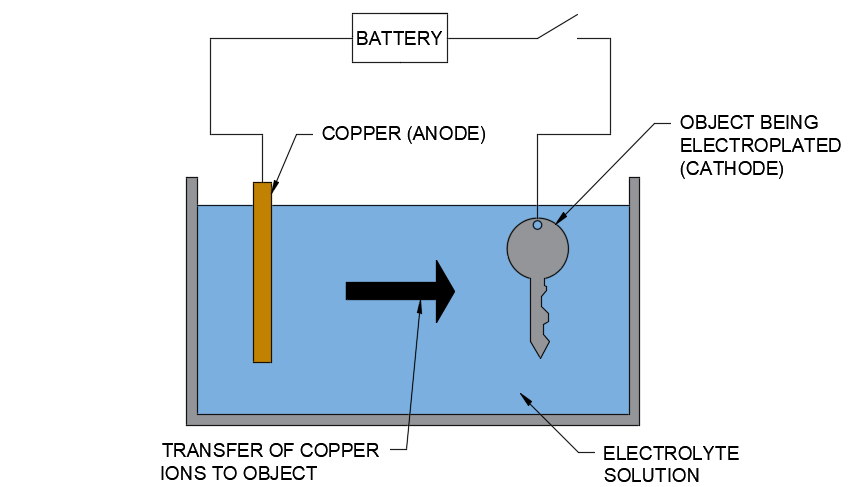

Electro-plating:

How it works:

- A cheap metal is coated onto a metal to protect it

- An electric current is passed through an acidic electrolyte

- The metal being protected (anode) then builds a layer of metal oxide

- Corrosion resistant

- Easy to do

- Improves mechanical properties

- Improves aesthetics appeal

- Cost effective

- Durable finish

|

- Time consuming

- Toxic fumes released

- Non-unifrom finish

|

Uses: Spoons, taps, shower heads

Powder coating:

How it works:

- The metal is heated to 230 degrees

- The metal is then dipped into polymer powder

- The polymer coating is then allowed to cool

- Range of colour finishes

- Non-toxic

- Evenly coated finish

- More protective than paint

- Better for environment that paint

|

- Harder to do than paint

- Uses energy/needs energy for heating powder (unlike paint)

|

Uses: Cars, wheel arches, sports equipment

Oil coating:

- Replaces oils in wood lost as timber dries out

- Hard wearing

- Protective finish

|

- Multiple layers needed to be applied

- Time consuming

- Labour intensive

|

Uses: Teak oil used on woods to give better protection

Galvanisation:

How it works:

- The metal is dipped into molten zinc

- The zinc acts as a sacrifical anode to protect metal underneath

- Prevents rusting/corrosion

- Simple process

- Quick process that can be done on a mass production scale

|

- Zinc layer can be chipped away over time

- Not a very aesthetic finish

|

Uses: Bridges, pipes, metal brackets

Cathodic protection (Impressed current and sacrifical anode):

How it works (Impressed current):

- Metal is connected to electric power supply which is connected to a cathode

- The cathode rusts over time whilst the anode (metal being protected) remains intact

How it works (Sacrifical anode):

- A metal which is more reactive is connected to the metal being protected

- The more reactive metal (sacrifical anode) rusts over time whilst the metal being protected remains intact

- Proetcts structures that are buried in dirt/water

- Greatly increases lifespan of metal being protected

- Cost efficent to run

|

- Hard to install

- Complex to upkeep

- Uses energy/needs connection for impressed current

- Expensive to install

|

Uses: Pipelines, ships, cars

Laminating:

How it works:

- Coating the paper with liquid/film to protect it

- Aesthetic/high quality look

- Rigid/strengthens paper

- Low cost

- Hard to tear/rip

|

- Paper hard to access/write on

|

Uses: Posters, pictures, song music

Varnishing:

How it works:

- Clear, non-pigmented ink used on pre-coated papers

- Enhances the colour of paper

- Protects against dirt/fingerprints

|

- Long dry time

- Slows down overall completion time - slower production rate

- Sticks to other surfaces/pages if not fully dried

|

Uses: Brochures, magazines

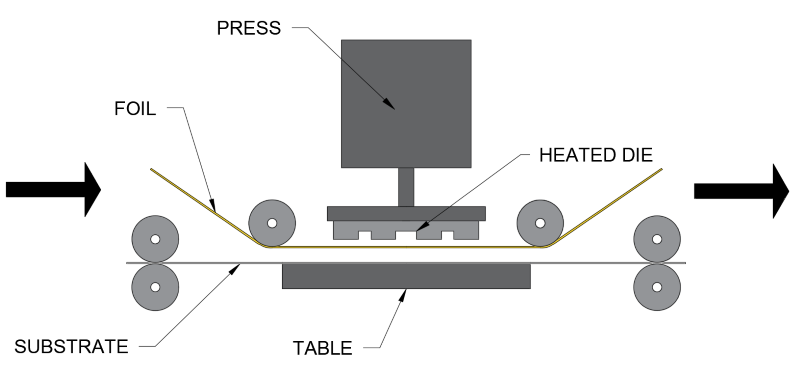

Hot foil blocking:

How it works:

- A foil sheet is place between the paper and the die

- The die is then pressed onto the foil and heated to allow the foil to join to the paper

- The die is then removed and the foil cools

- Enhances/adds value to paper

- Improved aesthetics

- Range of colours/foils etc

|

- If heated for too long the foil can bubble and melt

- If heated not long enough the foil will not stick

- Difficulty in reproducing tints and halftones

|

Uses: Passports, gold foil decorations, wedding invite cards

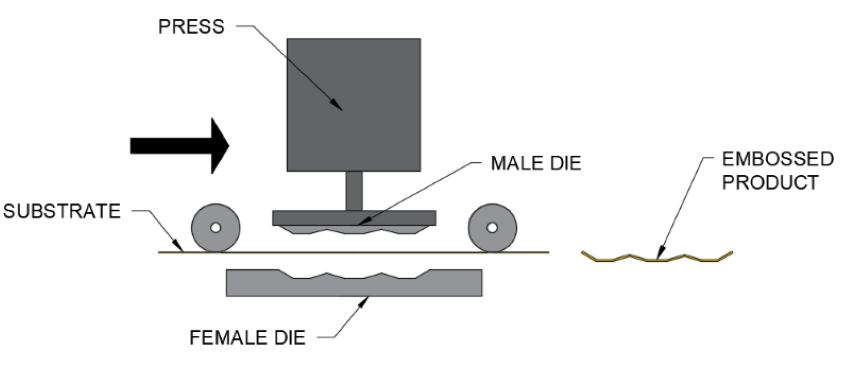

Embossing:

How it works:

- The paper is placed between the two formers

- The formers then close around the paper to form the shape

- Formers can be heated/cold

- High quality finish

- Sophisticated appearance

|

|

Uses: Toblerone card packaging, birthday cards

Topic test: